交易

-

活跃

-

芝麻信用

-

交易能力

交易额 - 高于0%同等级商家 -

买家数 - 高于0%同等级商家

-

活跃指数

0% 高于0%同等级商家

| Identification | ||||

| UNS Number | ||||

|

||||

| General Information | ||

| Description | ||

|

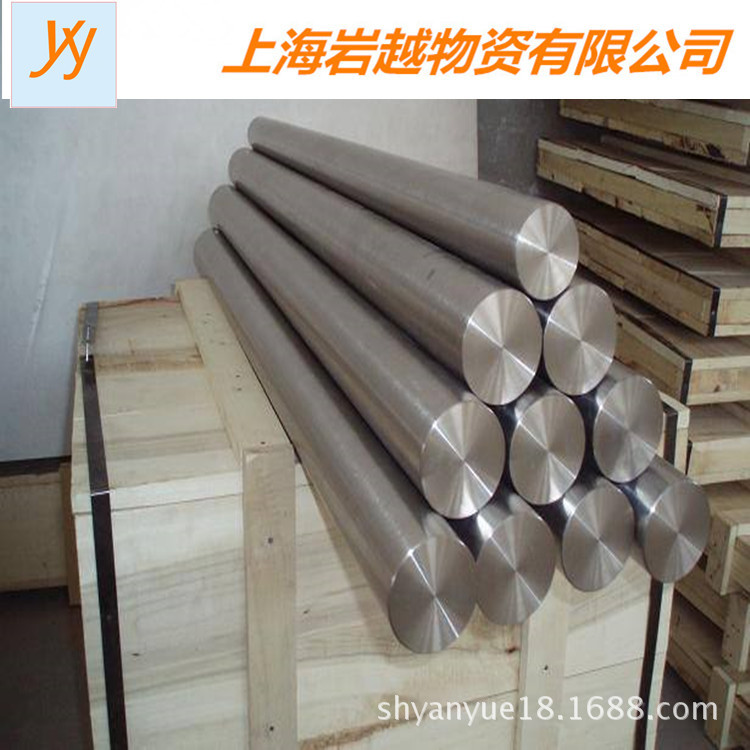

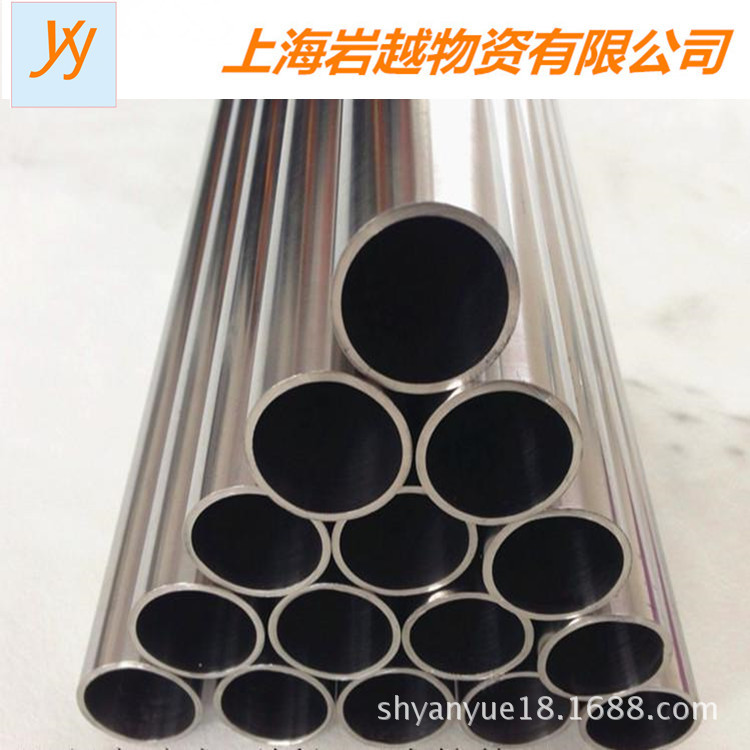

316L-SCQ® stainless is an austenitic stainless designed for use where extremely good surface finishes are required. The corrosion resistance and mechanical properties of 316L-SCQ stainless are similar to Type 316L. Typical specifications for bar products are ASTM A-276 and SEMI F20. |

||

| Applications | ||

|

316L-SCQ stainless could be considered for use in applications where cleanness, resulting in reduced inclusions, is advantageous in thin-wall components such as valves and fittings. |

||

| Corrosion Resistance | ||||||||||||||||||||||

|

Due to its superior corrosion resistance, the use of 316L-SCQ stainless has been extended to handling many of the gasses used in semiconductor manufacturing and chemicals used by chemical process industries. |

||||||||||||||||||||||

|

Important Note:The following 4-level rating scale is intended for comparative purposes only. Corrosion testing is recommended; factors which affect corrosion resistance include temperature, concentration, pH, impurities, aeration, velocity, crevices, deposits, metallurgical condition, stress, surface finish and dissimilar metal contact.

|

||||||||||||||||||||||

| Properties | ||

| Physical Properties | ||

| Specific Gravity | ||

| -- | 7.95 | |

| Density | ||

| -- | 0.2870 | lb/in3 |

| Mean Specific Heat | ||

| -- | 0.1200 | Btu/lb/°F |

| Mean CTE | ||

| -- | 10.3 | x 10-6in/in/°F |

| Electrical Resistivity | ||

| -- | 445.0 | ohm-cir-mil/ft |

| Heat Treatment | ||

| Annealing | ||

|

Heat to 1850/2050°F (1010/1121°C) and water quench. Brinell hardness approximately 150. |

||

| Hardening | ||

|

Cannot be hardened by heat treatment. Hardens only by cold working. |

||

| Workability | ||

| Hot Working | ||

|

316L-SCQ stainless can be readily forged, upset and hot headed. |

||

| Forging | ||

|

To forge, heat uniformly to 2100/2300°F (1149/1260°C). Do not forge below 1700°F (927°C). Forgings can be air cooled. |

||

| Cold Working | ||

|

316L-SCQ stainless can be deep drawn, stamped, headed and upset without difficulty. Since this alloy work hardens, severe cold forming operations should be followed by an anneal. |

||

| Machinability | ||

|

316L-SCQ stainless machines with chip characteristics that are tough and stringy. The use of chip curlers and breakers is advised. Since the austenitic stainless grades work harden rapidly, heavy positive feeds should be considered. |

||

| Additional Machinability Notes | ||

|

Figures used for all metal removal operations covered are averaged. On certain work, the nature of the part may require adjustment of speeds and feeds. Each job has to be developed for best production results with optimum tool life. Speeds or feeds should be increased or decreased in small steps. |

||

| Weldability | ||

|

316L-SCQ alloys are readily welded using Gas Tungsten Arc, Plasma, Laser and Electron Beam Welding techniques. Extra attention should be paid, however, to the weld penetration and bead geometry because of the effects on sulfur on the physics of the weld puddle. The penetration ratio (ratio of depth to bead width) increases with an increase in sulfur content up to about .03%. Conversely, the weld bead will become shallow and broader as the sulfur content decreases. The weld bead geometry and location can be a problem if components with significantly different sulfur levels are joined. Where possible, it is suggested that both components have similar sulfur contents. When this is not possible, good welds are possible between two components with significantly lower sulfur (0.004% vs.: 0.008 % sulfur) through carefully positioning the welding electrode and selection on the shielding gases. |

||

|

担保交易

资金保障更安全,先款后货,买家支付后货款冻结,收货后货款打至卖家账户。

即时到账

先款后货,买家支付后货款即时到达卖家账户,卖家再发货。

重要提示

-

关于洽谈:

买家可以通过龙腾数科平台即时沟通工具“钢叮”与卖家咨询商品信息、交易信息等问题,如果达成购销需求请进一步协商付款截止时间、交易方式、物流等相关事宜。

-

关于订单:

买卖双方购销需求达成一致后,订单由买家创建并推送给卖家,买家请在约定的付款截止时间之前确认并付款,逾期系统将自动关闭订单。

-

关于付款:

龙腾数科平台使用浙江网商银行作为卖家收款账户行,买家自行选择支付方式(网银转账/柜台转账),付款到卖家的网商银行(联行号:323331000001)账户,网商银行对保证资金安全起到了至关重要的作用,也支撑了担保交易的使用。

-

关于物流:

龙腾数科平台提供物流小单快运服务,1吨起运、快速响应,更多特色物流服务敬请关注 56.wuage.com。

-

关于安全保障:

龙腾数科平台提供交易安全保障服务,如果订单自动打款时间即将结束时,买家仍未收到货,可以通过“订单锁定”暂停自动打款时间,保证买家在收到货物后再支付货款。 订单进行过程中,买家如遇到任何问题,客服人员会协助买家联系卖家协调处理,客服热线:4006007272。